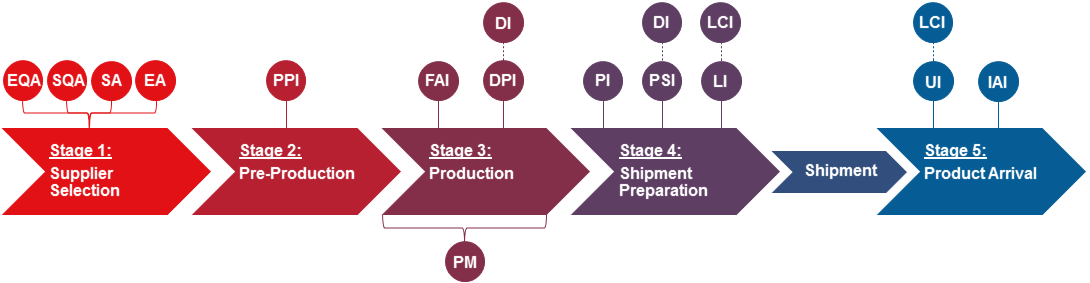

Our workflow, showing the inspections and audits done at each stage of the purchasing process for buyers and traders:

To help you ensure that the production of your product is being done in high-quality manner, we offer three varieties of production inspections:

- First-Article Inspection (FAI): This inspection is done at the beginning of production, but before mass production of your product begins.

- During Production Inspection (DPI): This inspection is done during the middle of mass production.

- Defect Inspection (DI): This inspection service is an optional addition to the DPI. It focuses on sorting out as many products as possible that have defects during production.

- Production Monitoring (PM): This inspection involves monitoring the production stage throughout several phases of the production process.

Why get a Production Inspection?

- See that your supplier is producing your products as required, at required stages of production

- Ensure that your supplier is implementing a proper quality control system to minimize defected products

- Check for defected products

Which Production Inspection is right for me?

To give you maximum quality assurance, we recommend our Production Monitoring (PM) inspection, as it covers several stages of the production process, to ensure that your products are being produced in a suitable manner from the first few sets to the final batches.

As a minimum, we recommend the During Production Inspection (DPI), which can be performed at whatever stage you would like during production (usually after around 80% of your products have been produced).

An optional addition to the During Production Inspection is our Defect Sorting Service (DSS), which includes checking for defects in the products that have been produced so far. It is useful for minimizing defects before the pre-shipment/shipment stage.

If you have a large order or are having your supplier produce a complex or new product, we recommend the First Article Inspection (FAI), which includes checking the condition of the first products being produced. It is very useful for avoiding defected products later in the production process.

If you are unsure about which Supplier Selection Audit(s) may be best for you, contact us and we can provide you with a free no-obligation consultation.

Where are Production Inspections performed?

We perform Production Inspections at supplier factories throughout Europe, the Middle East, Asia, and the Asian Pacific.

Why choose Tech Standard?

Ensuring the integrity of the production of your products can be a very difficult process if you cannot visit the supplier yourself or if you do not have the knowledge needed to make a proper assessment of the supplier’s production process. Tech Standard can put people at your supplier’s location (see locations below) with the competence needed to perform a proper assessment of the supplier’s production process.

© Tech Standard | Created with by The Pixcodev